JBS Sea Axe Controlled Flow Excavation Team Completes Phase 1 of the Subsea Greenlink Interconnector

TRACK RECORD

REGION

Europe

SECTOR

Oil & Gas

SOLUTIONS

Screw Conveyors

JBS was approached by a leading Oil & Gas service company, tasked with a challenging project for their client, a major Dutch Oil & Gas Operator. The project demanded a bespoke solution for material handling on a jack-up rig in the Dutch sector. The primary requirement was to develop a cuttings skip plan for zero discharge, encompassing the entire process from design and manufacture to installation on the rig.

This waste management system needed to align with the client’s stringent environmental goals without hindering drilling efficiency. Traditional screw conveyors were inadequate due to the consistency of the drilling muds, necessitating a custom-engineered solution from JBS. Additionally, the high volume of material meant that multiple discharge points were required, further complicating the design.

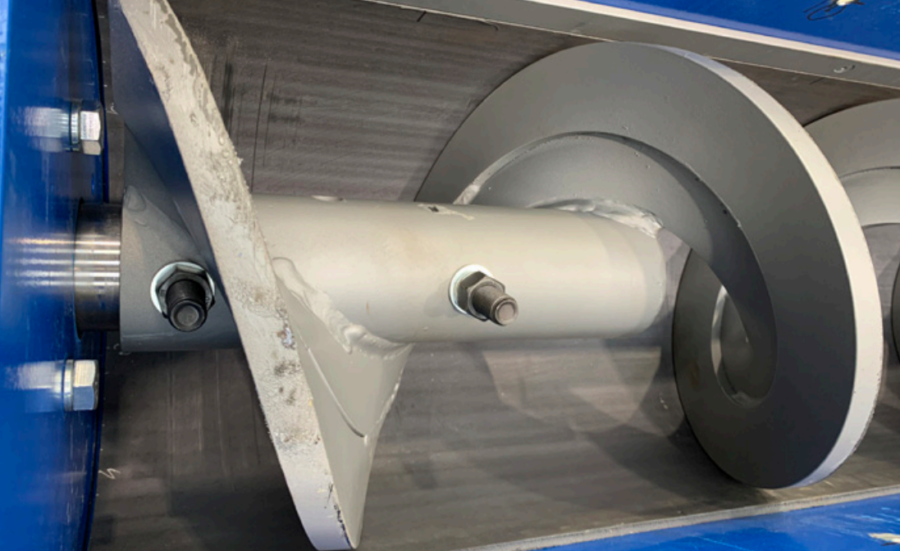

JBS designed and manufactured a bespoke twin conveyor system equipped with shaftless screws and Xylethon liners, tailored specifically for the unique properties of the drilling muds.

To complement this system, our fabrication workshops engineered and produced magic carpets and skip stations, ensuring seamless material handling. We also supplied all necessary supporting mechanical and ATEX electrical equipment to guarantee safe and efficient operations.

Before the final deployment, a trial fit was meticulously conducted at our Peterhead HQ to ensure all components met the standards required for offshore installations. Following this successful trial, our experienced offshore installation team travelled to the rig to execute the installation and integration of all components, ensuring the system was fully operational.

Our client was delighted with the outcome of the project. The execution was delivered on schedule, and the offshore installation team did an outstanding job. The rig is now fully operational, effectively managing material handling with the bespoke equipment performing brilliantly and as specified.

This project not only met the environmental objectives of zero discharge but also maintained high drilling efficiency, showcasing JBS’s ability to deliver custom-engineered solutions in complex and demanding offshore environments.

JBS delivers specialised engineering for deployment in marine and subsea environments — from precision controlled flow excavation (CFE) work on the seabed to delivering bespoke fabrication work for installation below the surface.

With headquarters in the North Sea port of Peterhead, our team are perfectly placed to support Marine & Subsea clients in the North Sea and other global regions,.