Arc Flash Enclosure

Portable Design

OUR SOLUTIONS

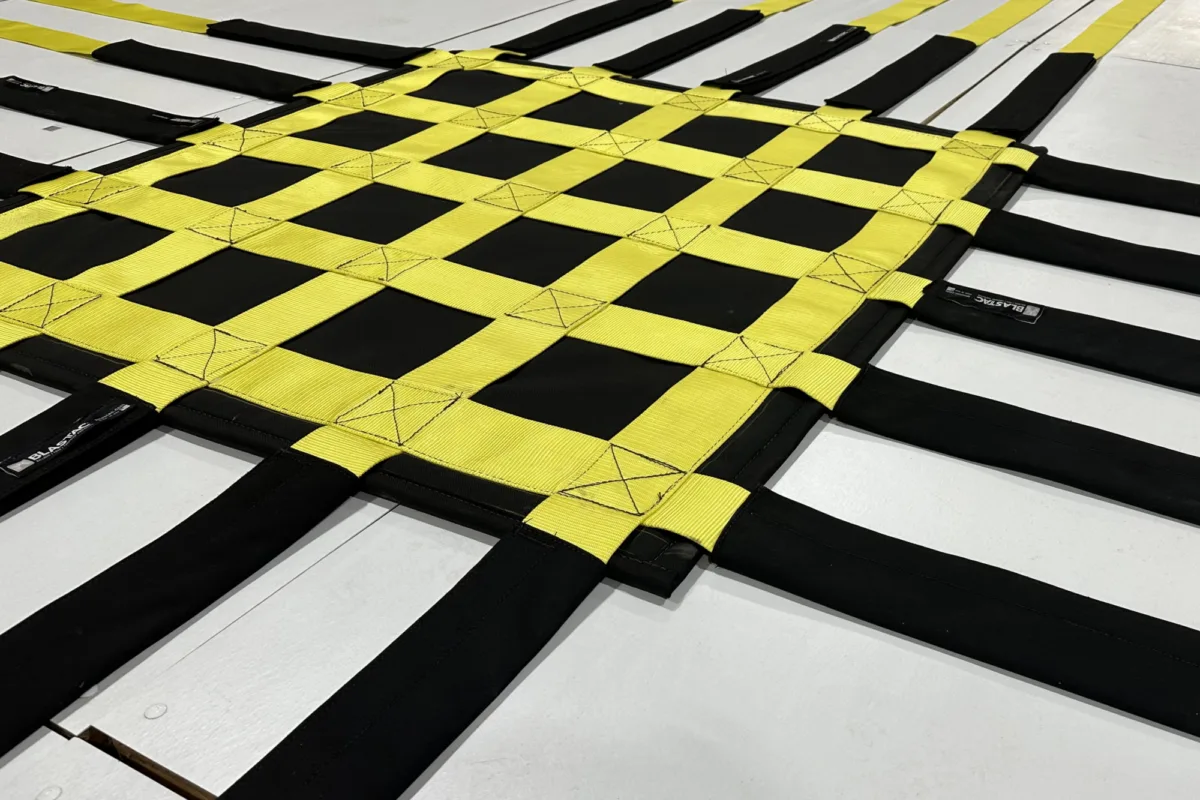

Blast Containment

JBS's world-leading BlasTac® blast containment product range offers comprehensive blast, frag, fire, ballistic and arc flash protection.

Trusted by a wide range of worldwide clients, BlasTac® utilises next generation fabrics to create the world's safest blast containment solutions — and the range is deployed internationally by clients in a range of sectors, including Oil & Gas, Aerospace and Defence.

Flexible and lightweight, all BlasTac® products have been independently tested and verified by third-party bodies to Lloyds Register, UL, DNV GL and ASTM international test standards. Certification is completed by Chesapeake Testing Labs in North Carolina, USA.

The World's Safest Solutions

for Blast Containment

Protects Personnel & Assets

BlasTac® provides the best available protection for staff and infrastructure during operations, projects and testing in high-risk environments.

Saves Lives

This equipment can prevent loss of life. To date, BlasTac® protection has shielded 35+ NYPD officers from direct ballistic hits.

Greater Cost Savings

One Oil & Gas operator saved $4.8m over an 18 month period during choke & kill manifold testing on an offshore North Sea rig.

Bespoke Solutions

Blast containment solutions can be tailored to clients exact requirements and installed globally, on-site, by qualified personnel.

Tested & Certified to International Standards

BlasTac® blast curtains and blast blankets are configurable to protect personnel and assets against:

- Explosions

- Fragmentation

- Ballistic

- Fire / High-Temperature

- Arc Flash

- Noise

Independently certified by Chesapeake Testing Labs, North Carolina, USA, BlasTac® products are tested in accordance with:

- U.S. Military / MIL-SPEC standards

- UL standards at Lloyds Register

- ASTM International standards.

- DNV GL standards

Third-party verification, assessment and certification by ExxonMobil, through their engineering partner Aker Solutions, completed the Lloyd's Register certification process for the entire JBS pressure test blast curtain solution range.

JBS' BlasTac® offering is a complete service — starting with initial site surveys and culminating in the final installation of blast containment in global locations.

This includes custom design and manufacture of protective curtains and frameworks to fit existing infrastructure, and portable, easily-storable options are also available for regular / intermittent testing, for example.

The BlasTac® range also includes ballistic protection options and high-temperature / fire protection using FireMax® 777 technology.

JBS ballistic protection products are issued with a V50 testing sheet and are NIJ 0101.06 compliant. The most common standards for testing the fragmentation resistance of a ballistic product are:

- US Standard – Mill STD 662 E

- UK Standard – UK / SC / 5449

- NATO Standard – STANAG 2920

For protection against high temperatures and fire, the SB72FM Series features FireMax® technology — a non-flammable woven fabric is designed to survive fire, heat and arc flash using a single blast curtain.

It will shed molten metal, certain chemicals, flammable liquids and other molten substances, while also being breathable, water-resistant and durable in harsh weather conditions.

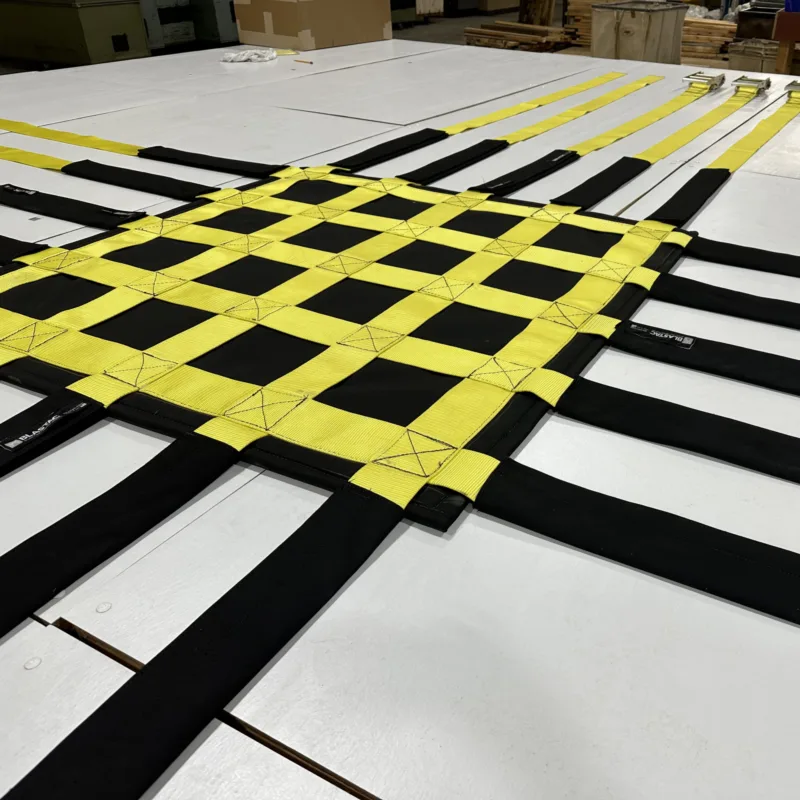

JBS portable pressure test bays (PPTB) allow clients to test equipment in a flexible and safe environment. They can be designed with full flexibility, and so can easily incorporate specific dimensions, logistics, handling and testing requirements — including:

- Open-top bays

- Front/back door options

- Multiple viewing panels

- Inside lighting

- Cabling and vents

- Extractor fans

- Camera equipment

PPTB solutions can also be easily combined with other BlasTac® products, such as FireMax®, and are designed for easy assembly, disassembly and storage.

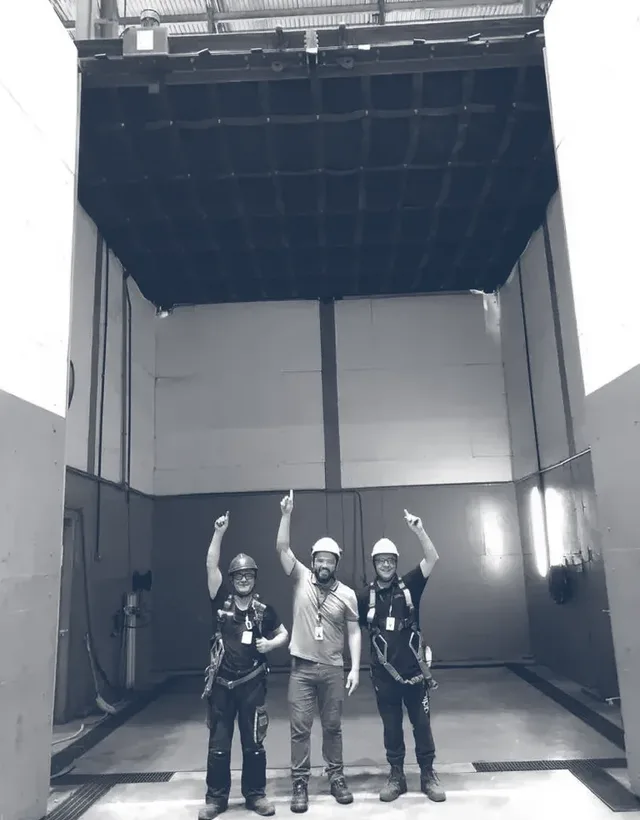

JBS are proud to offer clients our patented roof containment system for pressure test bays — designing, manufacturing and installing certified systems that use BlasTac® fabrics.

Our experienced team use Finite Element Analysis (FEA) to determine the threat level and design a roof containment system that provides the maximum test bay utilisation.

Manual and automated systems are available, with additional options including:

- CCTV

- Inside lighting

- Interlocks

JBS can design and manufacturee robust, bespoke blast canopy solutions that are designed to withstand high pressure and extreme temperatures.

Working closely with clients and integrating BlasTac® fabrics and FireMax® technology for maximum protection of personnel and assets, we can produce precisely tailored blast canopies that perform even in the harshest environments — all rigorously tested prior to delivery.

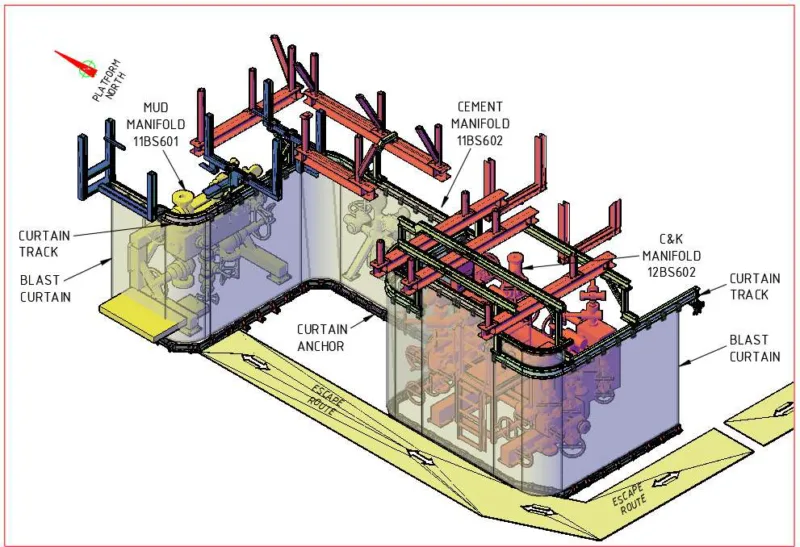

Located on offshore drilling platforms are the Choke & Kill, Cement & Mud HP Manifolds.

It has been identified that during pressure testing of these HP Manifolds, no SIMOPS can be undertaken on the drill floor due to location of the HP Manifolds.

To increase safety and operational efficiency, JBS install BlasTac® blast curtains around the drill floor HP Manifolds. Installation of JBS blast curtains, allow drill floor operations to continue whilst pressure testing of the HP Manifolds is ongoing.

Many types of blast curtain configuration are available to suit the installation. JBS typically survey the installation, discuss solutions with the offshore and onshore client teams, then propose the optimum solution.

Blast curtains consist of various smaller curtains which are secured together; this ensures the curtains are easy to open / close & also ensures all existing escape routes are maintained. Ballistic windows can be installed in the blast curtains to allow “eyes on” the equipment being tested.

When installed, the complete system is certified by JBS, with JBS providing calculated impact loads, FEA and structural calculations.

Live testing can also be carried out for any specific project applications.

Blast Containment for Safer Working Environments

A key motivator for the JBS team is understanding client circumstances and challenges, and the significance of helping to solve those challenges.

Blast Containment is one of several areas in which we do this for clients — each solution tailored precisely to meet requirements.

BlasTac® and FireMax® curtain

Offshore Oil & Gas Installation

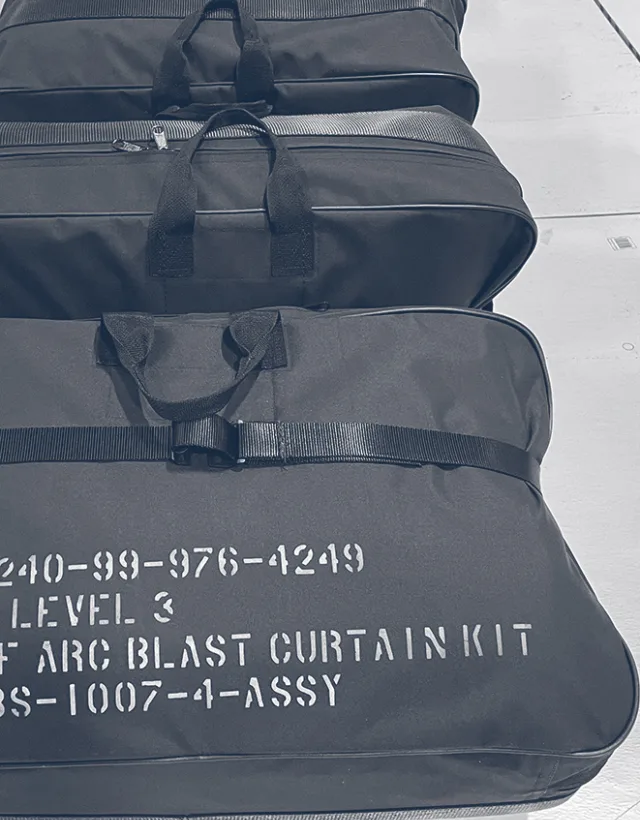

Arc Blast Curtain

Portable Storage Bags

Retractable Roof System

Pressure Test Bay

Want to know more?