JBS Sea Axe Controlled Flow Excavation Team Completes Phase 1 of the Subsea Greenlink Interconnector

TRACK RECORD

REGION

Norway

SECTOR

Oil & Gas

SOLUTIONS

Blast Containment

JBS were approached by Technip FMC (TFMC) in Stavanger, Norway, to design an automated roof blast containment solution for their gas test pit pool. This critical project required innovative engineering to ensure safety in a high-risk environment.

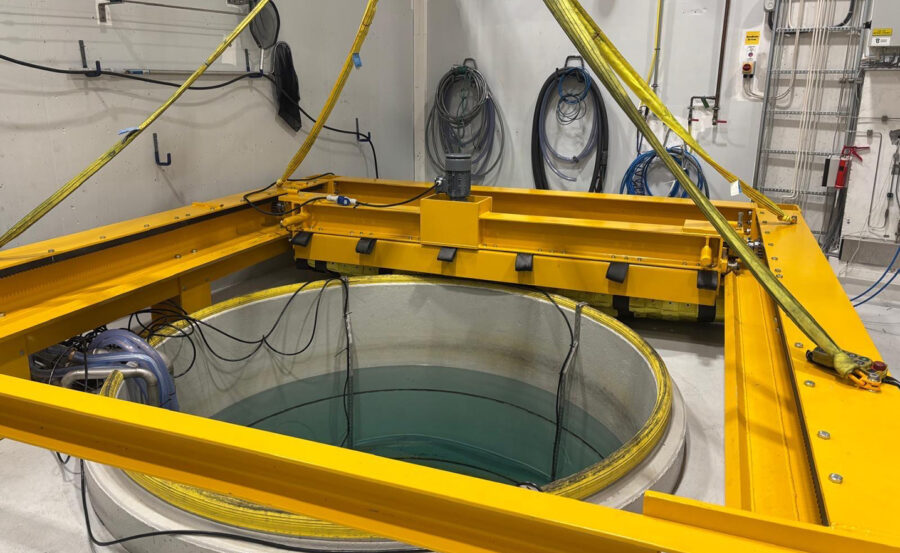

The gas test pit posed a unique and complex challenge. Filled with water, the pit needed a blast curtain capable of achieving two crucial objectives in the event of an explosion: allowing water to escape while effectively containing any fragments and projectiles.

Adding to the complexity, the working pressure for the chamber and its associated pipework - both gas and hydrostatic - was 20,000 psi. This high-pressure environment demanded a meticulously engineered solution that balanced safety, durability, and functionality.

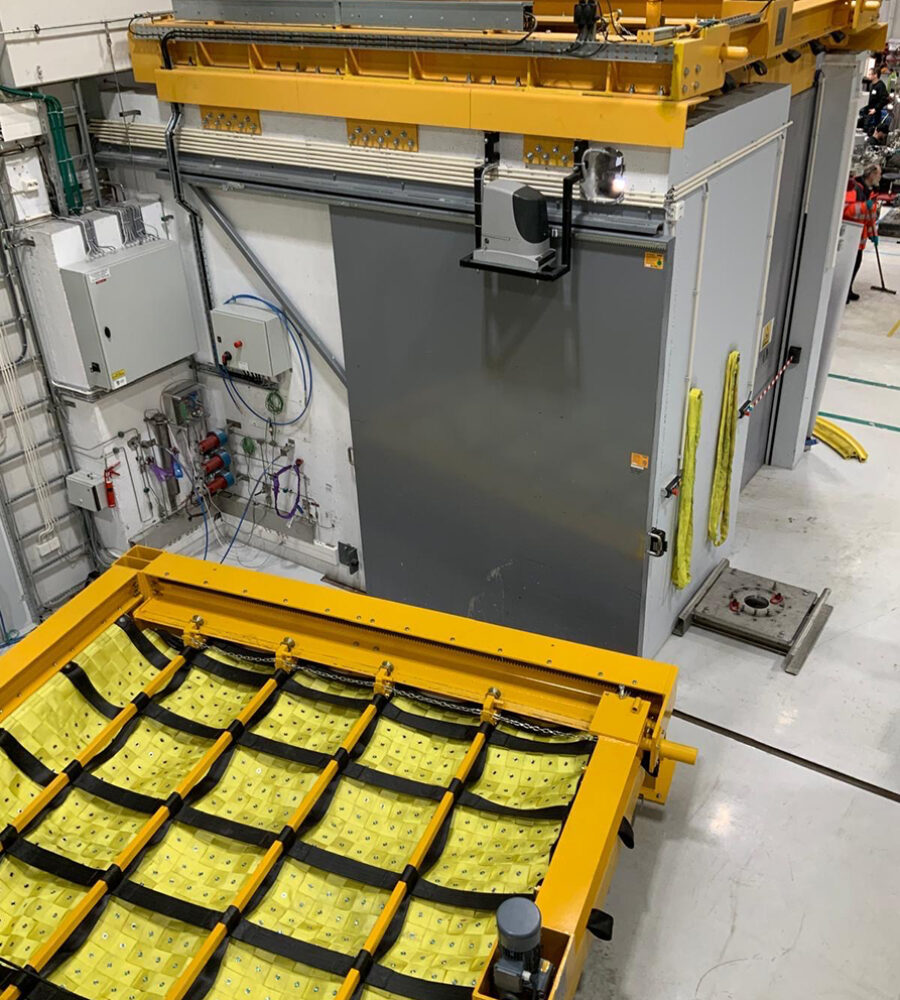

JBS engineers visited the site to assess the conditions and collaborate with the client on potential solutions. After extensive discussions and careful consideration of the unique requirements, JBS developed a fully automated motorised system featuring the SB424W webnet blast curtain. The design incorporated 10mm diameter military-grade grommets into the blast curtain.

These grommets were specifically included to allow the blast wave and water to escape upward during a catastrophic failure while ensuring the curtain retained all projectiles within the chamber. This design provided a reliable containment system that met the stringent safety requirements of the gas test pit.

To ensure seamless implementation, JBS manufactured the system to exact specifications and dispatched its installation team to Stavanger. The team successfully installed and commissioned the system, ensuring it was fully operational and ready to meet the demands of TFMC’s testing operations.

— Alexandre Cauduro, Production and Warehouse Manager

JBS's world-leading BlasTac® product range offers comprehensive blast, frag, fire, ballistic and arc flash protection.

BlasTac® utilises next generation fabrics to create the world's safest blast containment solutions — and the range is deployed internationally by clients in a range of sectors, including Oil & Gas, Aerospace and Defence.